Coriolis Composites brings its expertise to the automobile industry with the aim of to lightening vehicles to conform to the future regulation in effect from 2020.

Coriolis Composites’ machines manufacture composite complex geometrical structural parts that are light and crash resistant while decreasing material wastage.

3D LOCAL REINFORCEMENT

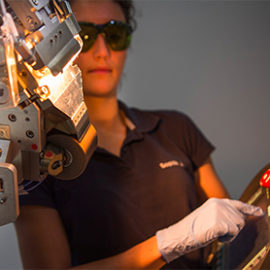

Coriolis Composites offers a Coriolis Csolo allows the local reinforcement of different structural parts, such as engine mount or backseat. Local reinforcement can be over molded or can be in-situ consolidated onto a thermoplastic part.

Advantages

/ Reduced part cost due to the limited use of continuous fiber combined with low-cost injected polymer.

/ Highly productive because of reduced layup cycle time

/ Highly robust and mature process of over molding

/ 0% scrap

/ Can be adapted for any kind of shape and dimension of automotive part

Solutions

Part made with local reinforcement can be made following two processes:

- Local reinforcement can be laid up with in-situ consolidation and then over molded,

- Local reinforcement can be laid up over a thermoplastic part with in-situ consolidation.

2D TAILORED STACKS

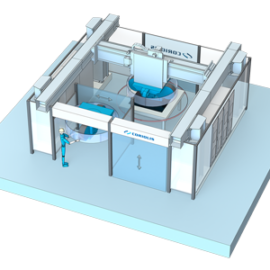

Coriolis Composites offers a Coriolis C5 Compact allows the production of tailored stacks reinforcement of different structural parts, such as B-pilar, door reinforcement.

Advantages

ZERO WASTE AND PERFORMANCE

/ Reliability of the machine assuring use in 3 shifts in 5/7 days in particular by using material aimed at avoiding fouling

/ High productivity by laying several fibers simultaneously at high speed

/ Optimal mechanical performances combined with a maximum weight reduction by optimizing the orientation of the fibers, thicknesses and variable contours

/ Zero waste rate by cutting on the fly for making the layers « net shape »

/ Forming or stamping optimized by using independent fibers and consolidated layers

/ Capability to lay up low cost materials

/ Compactness of the machine for a small floor area in production factories

/ Rapid commissioning and replacement due to a compact structure and safety integrated into the design

Solutions

- Capability to lay up low cost thermoset, thermoplastic prepress or dry fiber

- Compact layup machine for producing parts with an average dimension of 1x1m, average thickness 2 mm, with the objective of a rate of 1 part / minute.

PREFORM

Coriolis Composites offers an innovative and exclusive process of dry fiber functionalized preforms.

Advantages

FORMABILITY AND STIFNESS

/ High permeability for injection

/ High formability

/ Good stiffness of the preform to ensure good handling

/ Capability to be accurately trimmed

Solutions

Coriolis Composites’ proprietary process of dry preforms ready to be injected, made from dry direct fibers.