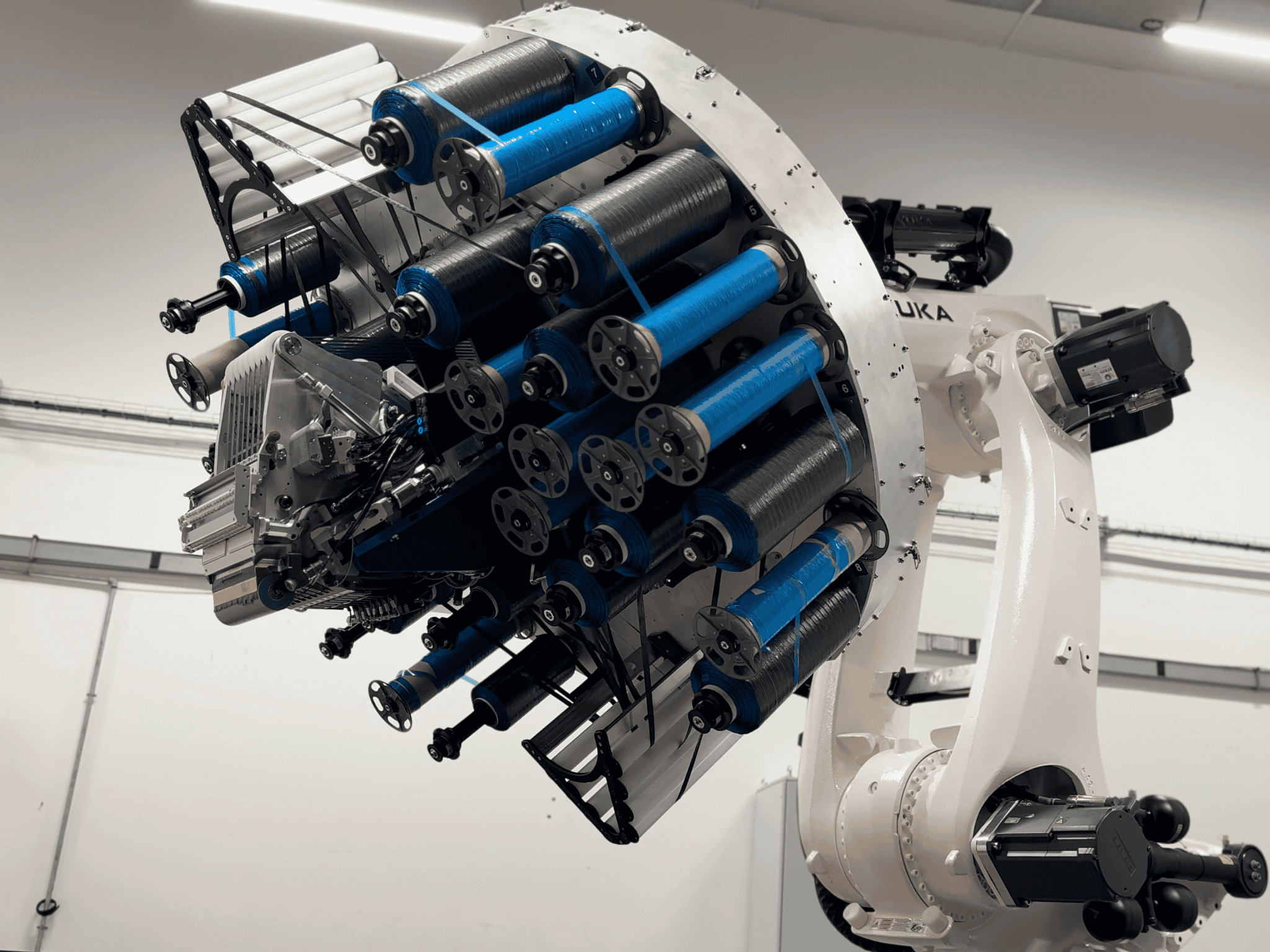

Fiber placement dockable head for large parts

Advantages

High speed layup with gantry and robot

1/2” and 1/4” thermoset, thermoplastic and dry fiber manufacturing capability

Suitable for large curved parts

Applications

Fuselage & panel

Concave or convex panels with double curvatures

Complex parts with narrow radius

Spar & frame

High compaction around edges

Ply drop-offs and ramps over corners

Technical informations

AFP process specifications

| Fiber width | 1/4 and 1/2 in |

| Head configuration | 8 and 16 spools |

| Cut and feed repeatability* | ± 2.5 mm at 1 m/s |

| Compaction force control | 10 N/mm |

| Maximum lay-up speed* | 1.5 m/s |

| Tolerance between course laid up on separate tapes | +2.5/-0 mm |

| Minimum distance between cutting and feeding an individual fiber** | 10 mm |

| Minimum fiber length* | 90 mm |

| Dynamic head compliance | ±5 mm |

| Dockable head | Carbon fiber spools embedded in the head |

| Docking station for multiple heads | Active or passive station |

| Material heating source | IR or Laser |

| HMI for advanced production management | Coriolis HMI V5 |

| Offline programming software | Coriolis CADFiber® and CATFiber® |

| Controller | Sinumerik One |

| Head carrier | Robot KR800 or Gantry |

Robotic cell configuration

| Robot | Kuka KR 800 or Titan |

| Horizontal axis positioner | From 6T to 2x40T |

Gantry cell configuration

| X Y Z AXES | |

| Stroke | X : 20m, Y : 7m, Z : 2.1m, |

| Speed | X : 70m/min, Y : 90m/min, Z : 120m/min, |

| Acceleration | X : 2m/s², Y : 3m/s², Z : 4m/s², |

| Positional Accuracy | X : ±0.10 mm, Y : ±0.10 mm, Z : ±0.10 mm, |

| Repetability | X : ±0.05 mm, Y : ±0.05 mm, Z : ±0.05 mm, |

| A B C AXES | |

| Stroke | A : ±100°, B : ±25°, C : ±200°, |

| Speed | A : 2.62 rad/s, B : 0.80 rad/s, C : 8.4 rad/s, |

| Acceleration | A : 8 rad/s², B : 5 rad/s², C : 17 rad/s², |

| Positional Accuracy | A : ±25 arcsec, B : ±25 arcsec, C : ±25 arcsec, |

| Repetability | A : ±15 arcsec, B : ±15 arcsec, C : ±15 arcsec, |

Materials

| Thermoset prepreg | 135 to 268 gsm dry |

* Depends on the material, heat source and part shape and controller

** Lay-up speed can be limited

Get in touch with Coriolis

Feel free to contact us to discuss you composite part automation project. We’re here to help you, every step of the way from the design until the manufacturing.

Rue Condorcet – Z.A. du Mourillon

F-56530 Quéven

Tél : +33 2 97 59 94 98

About us

Our offer

Follow us

© 2023 – Coriolis, made with ❤️ by Lamour du Web