Human Machine Interfaces developed by Coriolis Composites allow operators to set up the machine, operate it online, manage offline functions as a background task and trace machine parameters during lay-up ensuring traceability of operations.

A USER-FRIENDLY OPERABLE SOFTWARE SUITE

Touchscreen mobile console

The mobile console enables to operate the robot from inside the safety perimeter during the test phase: manually move the robot to a specific position, execute pre-programmed robot routines and probe the mold. It also carries out head maintenance.

Touchscreen fixed console in the operator room

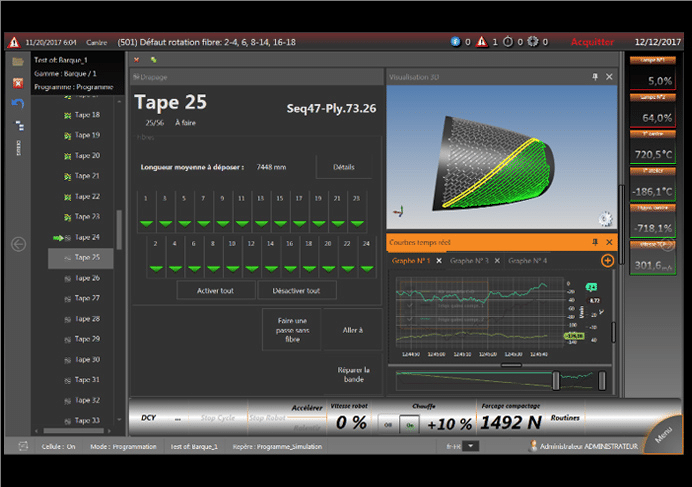

PRODUCTION PAGE

Once the manufacturing program has been validated, the online HMI can start the production and monitor returns, errors or alarms. The operator visualizes the real-time curves for sensor measurements and the 3D part and the lay-up status of the tapes. Operators can thus carry out inspections and take the necessary actions.

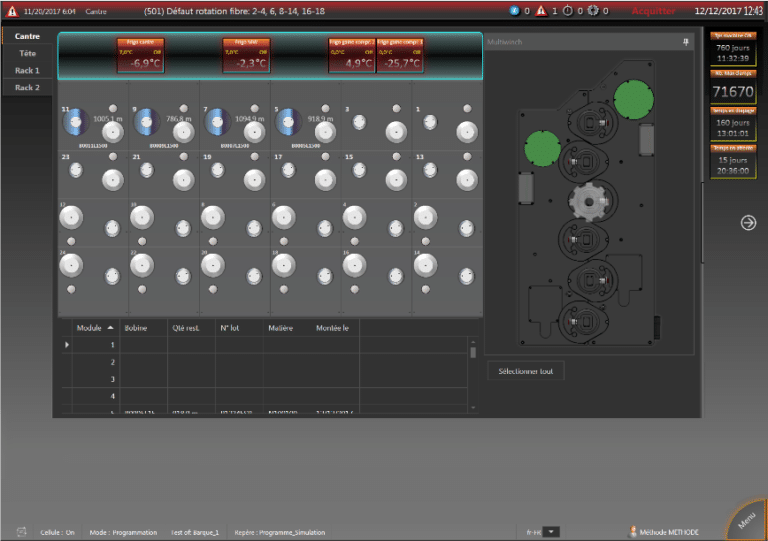

MACHINE PAGE

The online HMI displays the status of the machine: creel (material loaded), material level on each bobbin…). All instantaneous values of the sensors can be selected and controlled (pressure of a cylinder, room hygrometry, temperature in the creel, etc.) as well as those of the head counters (how many cuts per knife for example). This enables the operator to monitor the machine and to plan maintenance operations.

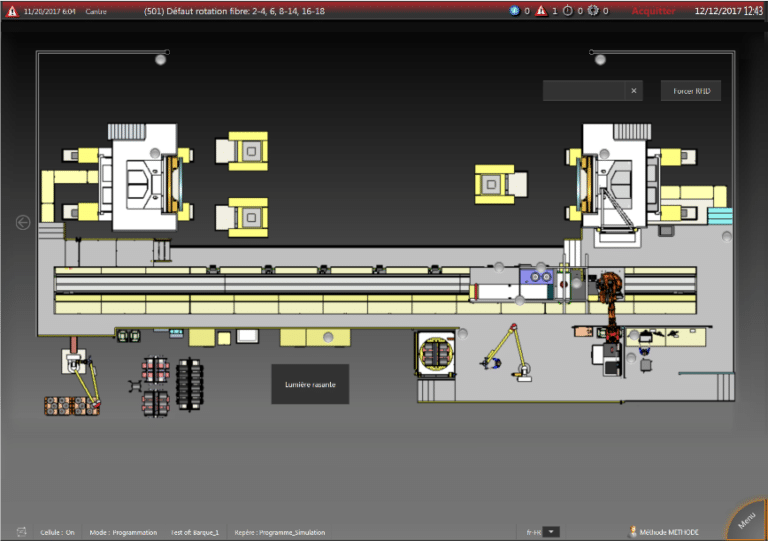

HOME PAGE

The online HMI offers a 3D view of the entire cell to visualize information that impact the machine: an emergency stop that has been activated, creel door open or closed etc. It can also offer tailor-made features.

HMI Manager

The offline HMI manager can be installed nearby or in a remote office. It enables the management and administration of the machine: creation of user accounts (setting of the rights, profiles, preferences…), production management with creation of manufacturing orders, loading of programs and settings of production cycles, mold management, management of probing data, management of the spools (remaining length, expiry date, batch number) and maintenance of the cell (import / export calibration, cutting counters, time of use, reset of the values).

EXTRA FUNCTIONNALITIES TO MEET YOUR NEEDS

All our efforts are focused on your business needs. Our engineers and designers work all year long on innovative functionalities and ergonomics of your HMI.

HMI STORE

The HMI Store collects all the data produced by the machine during the production of the part. This can be set up according to your needs. Data extraction can be automatic but also manual.

EXTRA OPTIONS ON-DEMAND

Laser projector Faro tracer: this option can be released with your HMI online thanks to the Faro RayTracer software to pilot laser projection on ply, tape and fiber contours.

MES/MOM interface: Coriolis Composites proposes to interface its HMI with your Manufacturing Execution System – MES or Manufacturing Operation Management – MOM software to check your programs and to manage your production orders and traceability data.