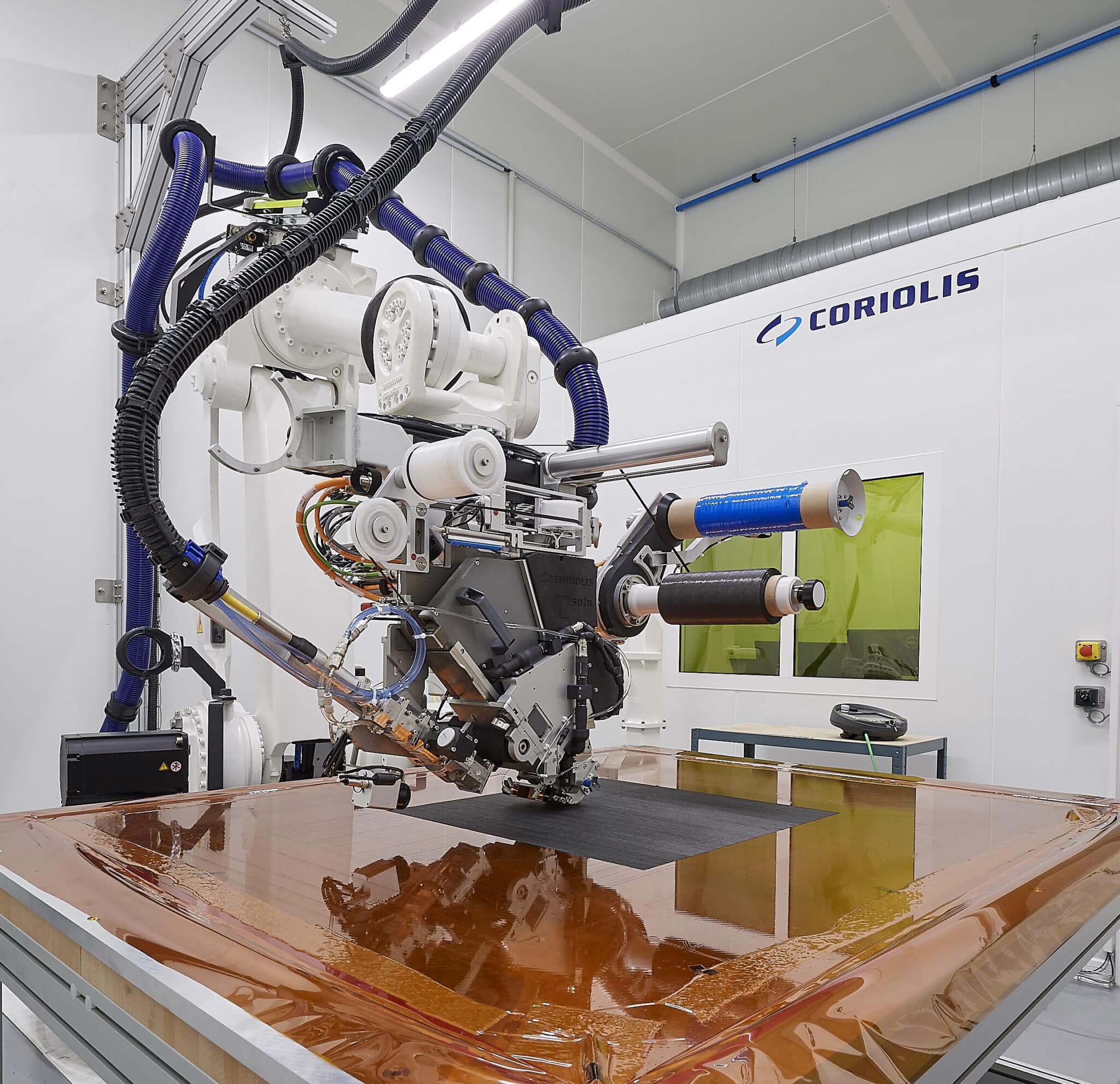

A state-of-the-art workshop to support your AFP/FW part development projects: capabilities and strengths of Coriolis Composites are fully dedicated to your success.

A confidential zone for your AFP/FW part projects

The Composite Center follows your industrial or research projects from the feasibility part study until the validation of the performances of your machine.

Beyond the validation task, the Composite Center secures the development projects for your benefit, whilst giving you the chance to familiarize yourselves, ahead of time, with Coriolis Composites technology. The Composite Center houses your demonstrators as well as special preproduction series.

Equipment available in our Composite Center

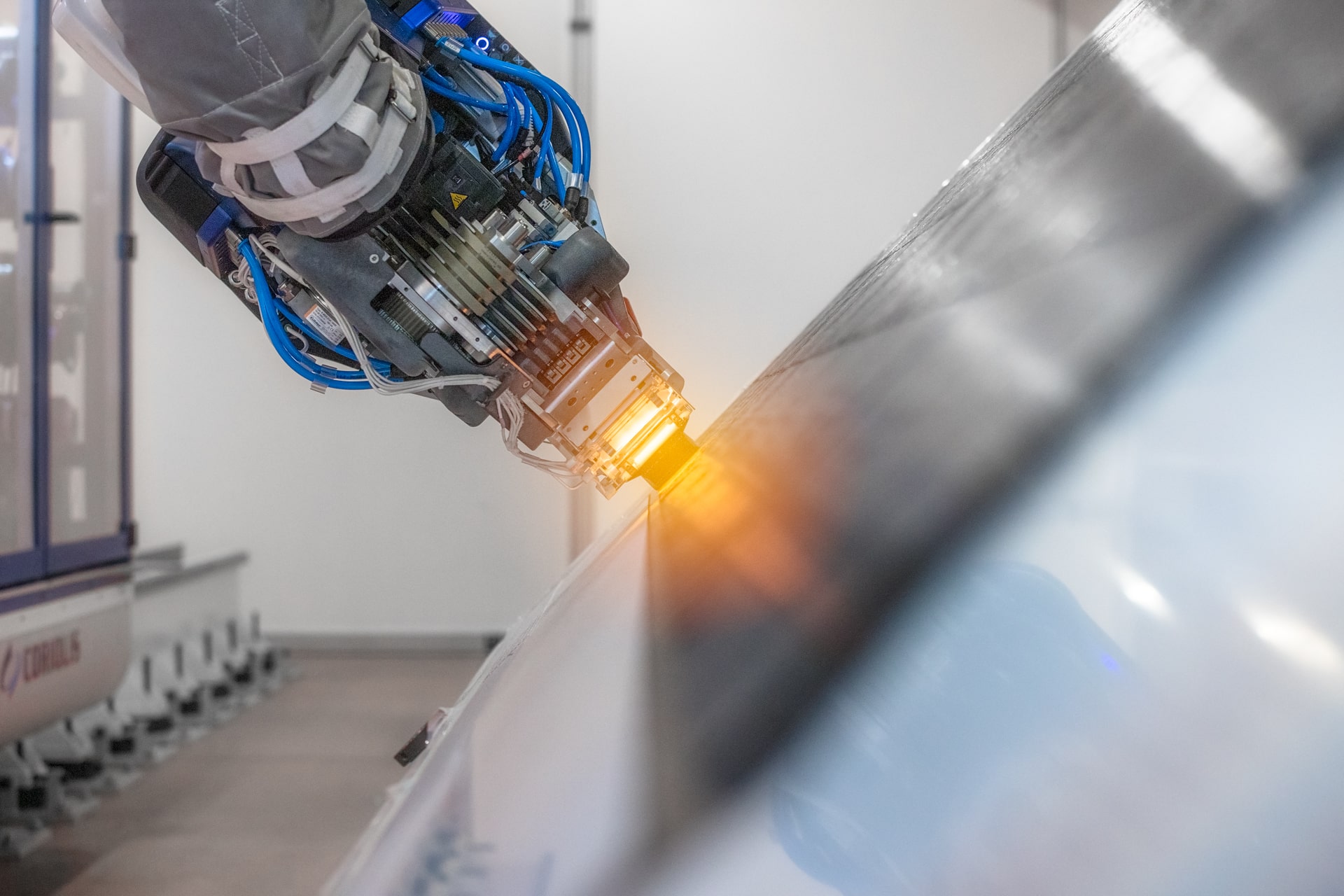

Best in class in Automated Fiber Placement processes, Filament Winfing processes and composite expertise, the Composite Center hosts various collaborative projects, R&D material trials and new process development.

Coriolis C1.2

FRANCE

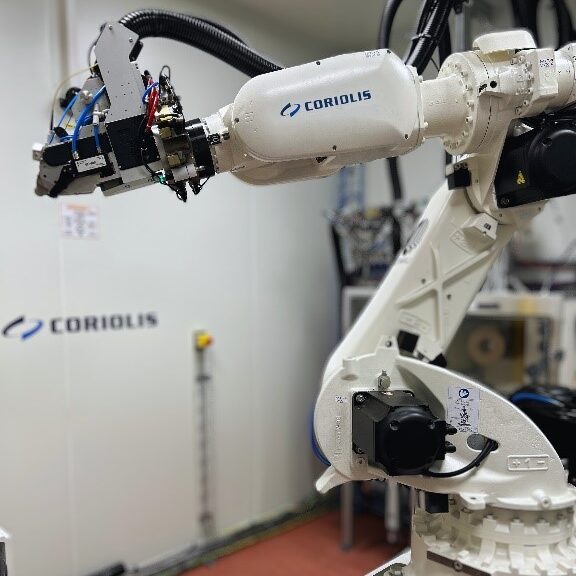

Coriolis Csolo

FRANCE and GERMANY

Coriolis Cpico

FRANCE

MFTech Profil1

FRANCE