We can propose a range of machine with robot and gantry for large component manufacturing

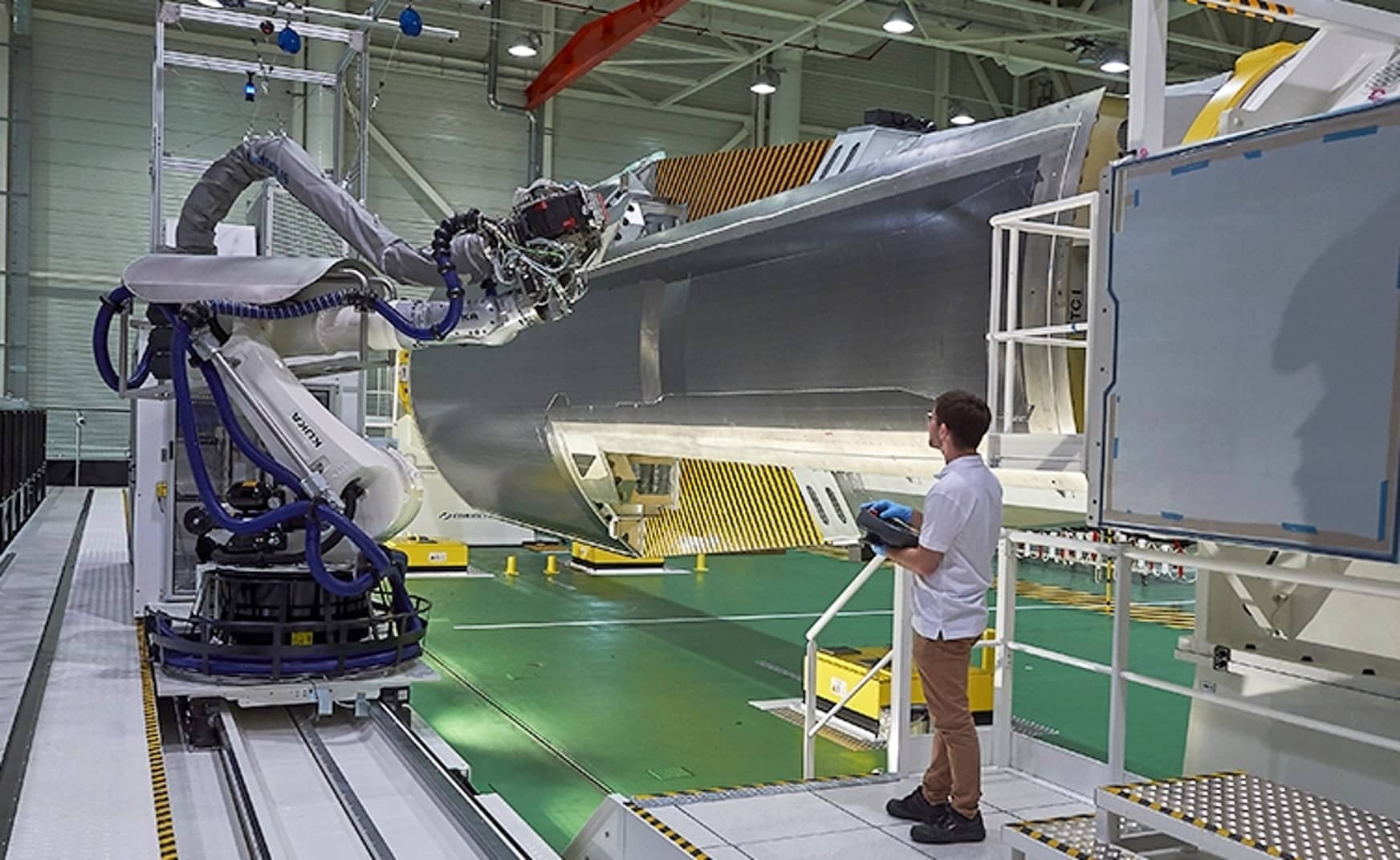

Coriolis C3

Fiber placement dockable head for large parts

We can propose a range of machine with robot and gantry for large component manufacturing

Need more information?

PRODUCTIVITY AND DIMENSIONS

Substantial productivity thanks to the high layup speeds and large parts

Choice in the tape width from 1/4”, 1/2” or 1.5”

Substantial thicknesses with straight edges without having to put wedges or shims in place

Capability to produce big parts with the gantry machine architecture

Flexibility with dockable head

Fiber placement system for 16 fibers with dockable head using Kuka KR 800 robot or high rail gantry.

Maintenance improved thanks to dockable head sytem

Feel free to contact us to discuss you composite part automation project. We’re here to help you, every step of the way from the design until the manufacturing.

Rue Condorcet – Z.A. du Mourillon

F-56530 Quéven

Tél : +33 2 97 59 94 98

© 2023 – Coriolis, made with ❤️ by Lamour du Web