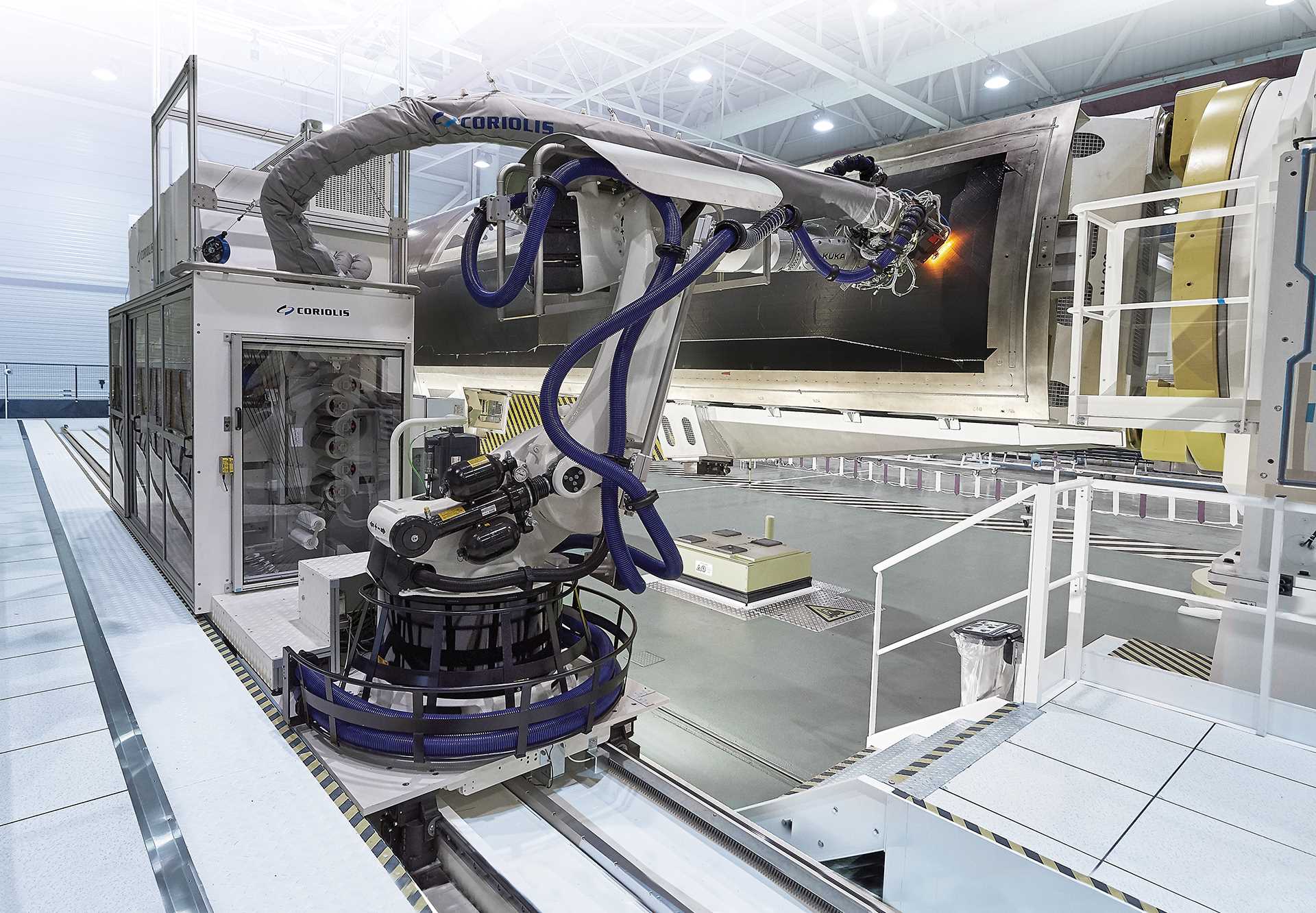

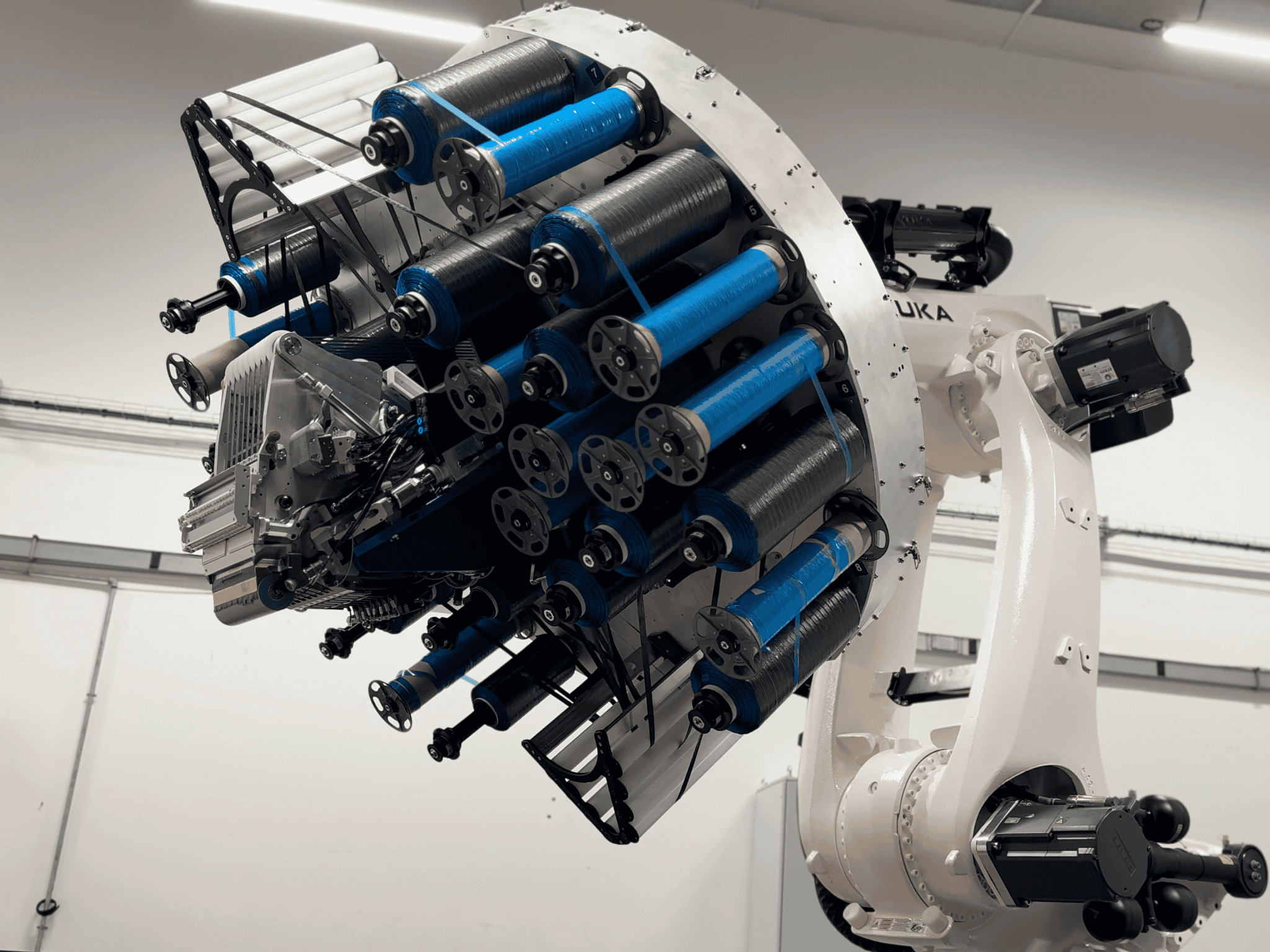

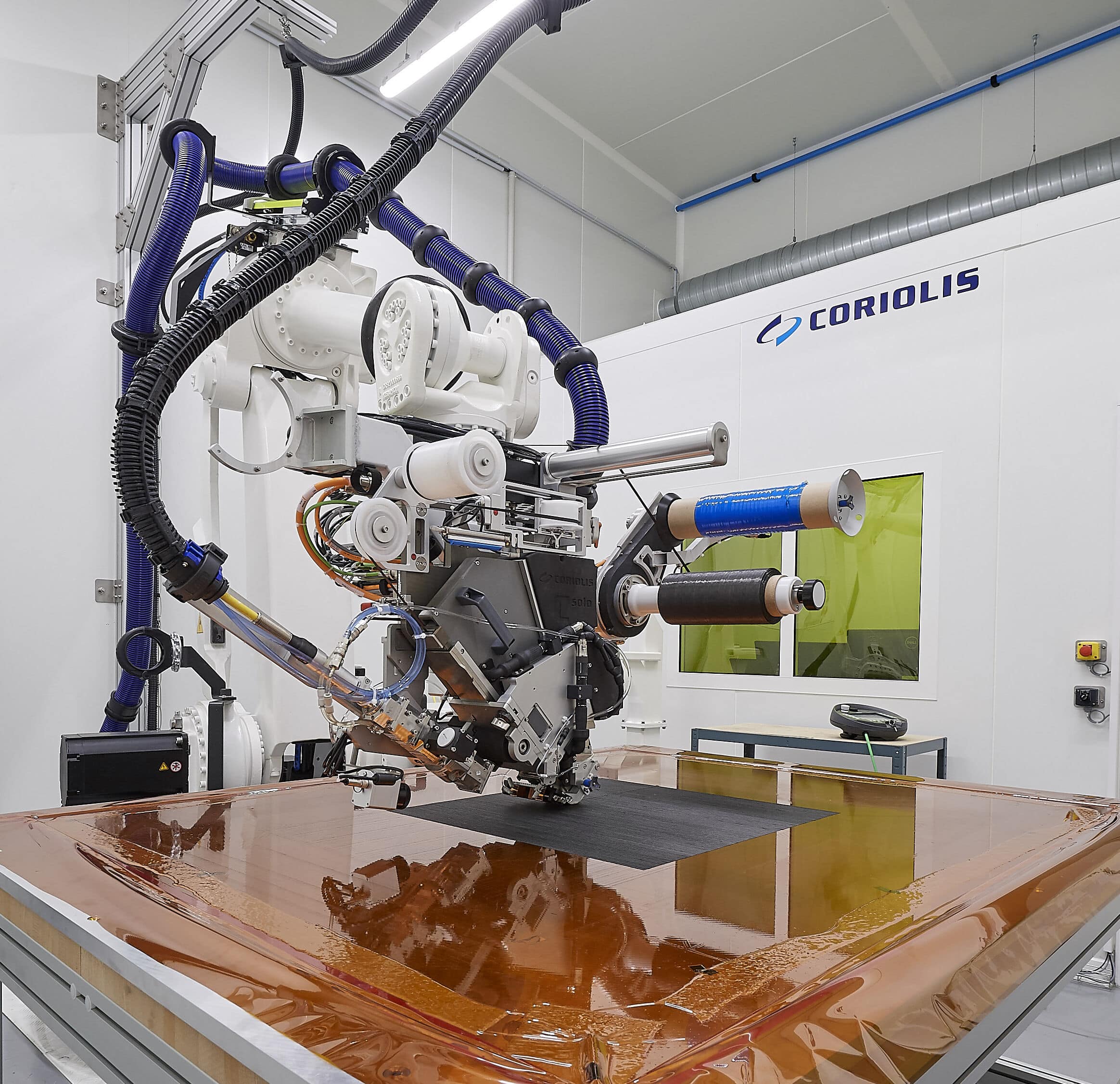

Fiber placement machines

20 years of experience in automated fiber placement with more than 170 machines installed worldwide.

Options

Coriolis Composites also offers options of for all its machines such as Automatic Inspection or HMI advance features

Automatic Inspection System

Automatic Inspection System (AIS) had been developed to run this inspection autonomously during the layup.

HMI

To increase the AFP experience, several HMI advance features are available, such as : the closed loop, CoDa, …

CoDa

CoDa : CoDa is a software developed to simplify the data monitoring of the machine.

Get in touch with Coriolis

Feel free to contact us to discuss you composite part automation project. We’re here to help you, every step of the way from the design until the manufacturing.