Flexible, compact, versatile, fiber placement cells adapt easily to different geometries and ranges. It enables the manufacture of complex parts and is suitable for industrial applications as well as for the applications of research centers which can easily manage a high number of options.

Revolutionizing the composite manufacturing process

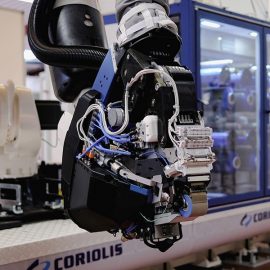

Coriolis Composites fiber placement technology is based on a set of unique patents: a creel (or bobbin cabinet) situated at the foot of the robot, a flexible fiber feeding system from the creel to the placement head and a compact and light placement head to place individual fibers onto the mold.

The state of the art of automatization

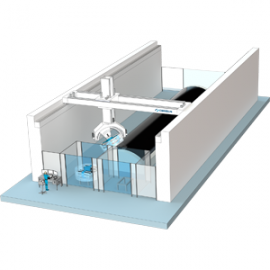

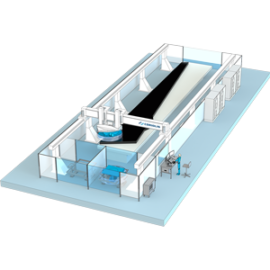

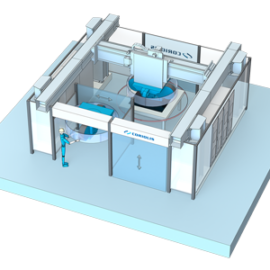

The fiber placement systems developed by Coriolis Composites are mounted on 6 axis poly-articulated robots. To enhance their capacities, external axes can be added as a positioner for the mold or a rail for the robot. The set, often composed of 8 interpolated axes, is called “a robotized cell” or AFP Cell. This meets the most demanding industrial specifications and expectations for series production, such as precision layup and cutting, as well as repeatability and reliability.

To boost the performance of every industry

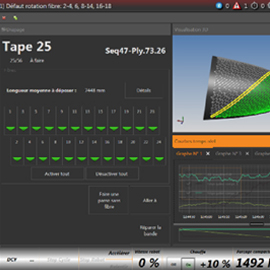

This modular and flexible conception offers a large range of possibilities and offers customers an optimal configuration for their specific applications as well as a perfect Human Machine Interface (HMI).

Robustness and adjusted budget

The fiber placement systems are offered at an affordable budget combining quality, productivity, reliability, handling and easy maintenance. They are supplied with the latest generation Kuka Quantec robots. These standard robots offer both a good rigidity and high precision, all combined with a high dynamic movement.