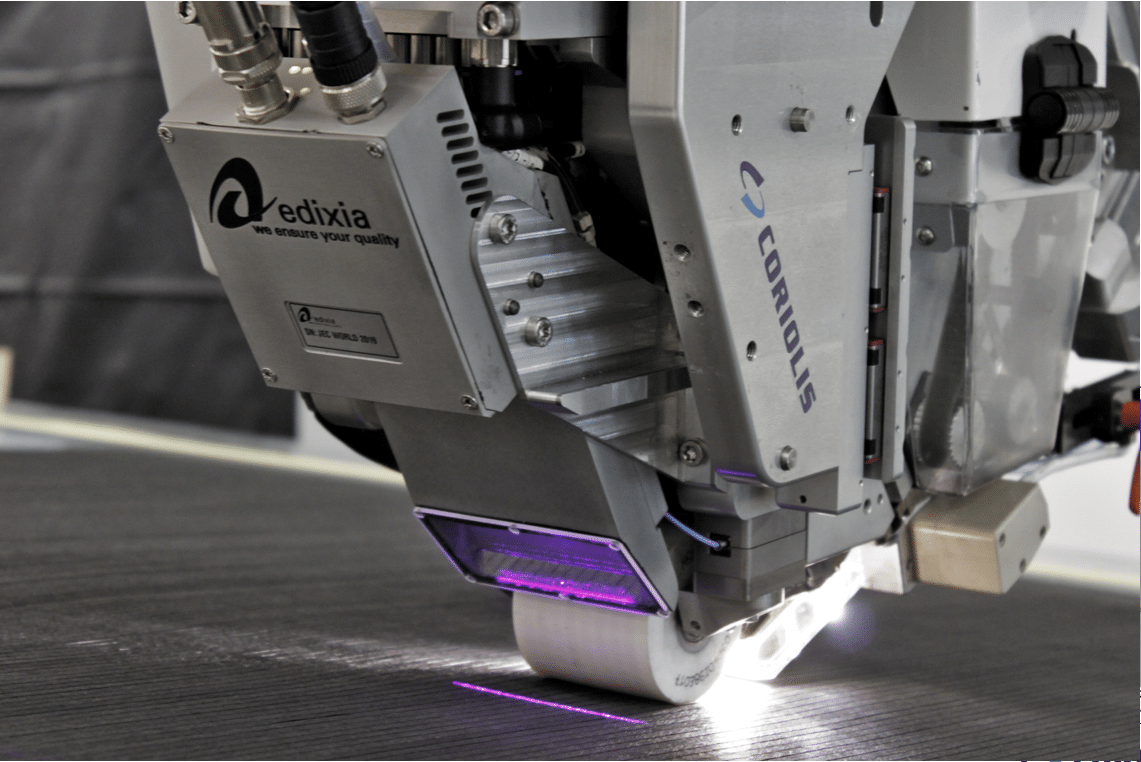

CORIOLIS in process Automatic Inspection System for Automated Fiber Placement for C1 & C1.2 machine.

Advantages

Inspection at the AFP lay up speed

Coriolis AFP head compacity maintained

Ability to inspect complex part

Technical specifications

AIS Hardware

| Fiber configuration | 8*1/4” and 16*1/4” |

| Compacity | Head compacity kept |

| Inspection speed | Up to 1.2m/s |

| Measurement distance | Short measurement distance after the roller |

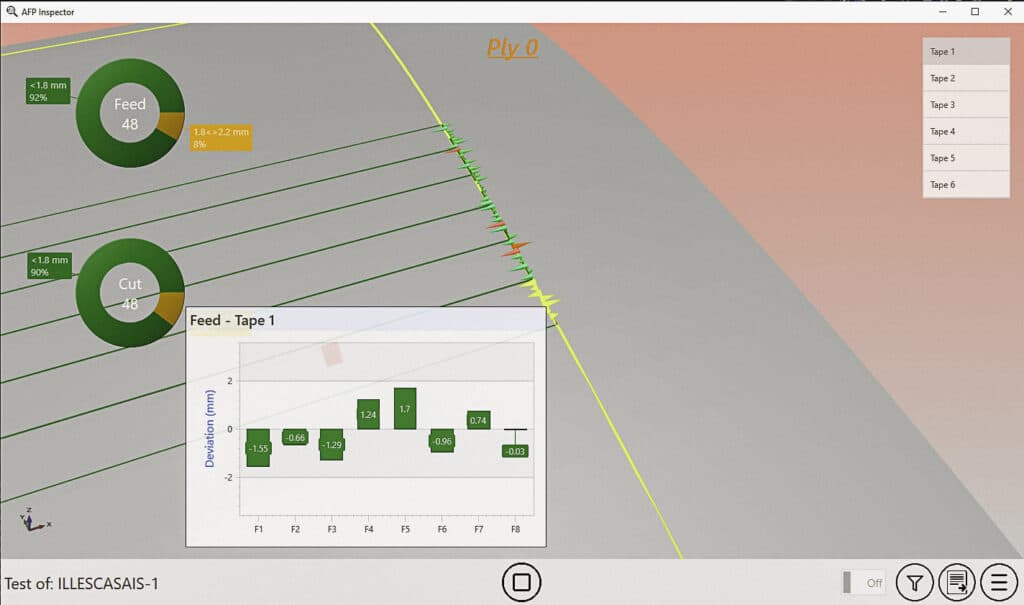

AIS Software

| HMI | Fully integrated in Coriolis HMI V5 |

| Viewer | Operator 3D viewer |

| Mode | Offline to post analysis & export of the data in standard format |

AIS specifications for V1 version – Available now

| Qualified for Thermoset material | |

| Validated for 2D application | |

| OK for Gap & Overlap detection. Mini sizes: | |

| Length | 5mm (0.2 in.) |

| Width | 0.3 mm (2.42 in.) |

| OK for FOD & Fuzzball detection. Mini sizes : | |

| Length | 3 mm (0.12 in.) |

| Width | 3 mm (0.12 in.) |

| Height | 0.18 mm (0.007 in.) |

| OK for twisted tows detection. Mini sizes: | |

| Length | 5 mm (0.2 in.) |

| Width | 3 mm (0.12 in.) |

| OK for Fiber waviness detection. Mini sizes: | |

| Length | 3 mm (0.12 in.) |

| Width | 3 mm (0.12 in.) |

| Height | 1 mm (0.04 in.) |

AIS specifications for V2 version – Available in the future

| Addition in the detection software |

| Add & Cut detection |

| Overlap detection |

| Splice detection |

| Corner path detection method |

| 3D Shape inspection |

| Analysis & visualization software |

| Sector gap measurement |

| Cumulative analysis of the whole ply |

| Linked to laser projection for fast repair on the part |

| Hardware |

| No futher development on the device compare to V1 |

| Compatibility with Thermoplastic and Dry Fiber materials (laser) |