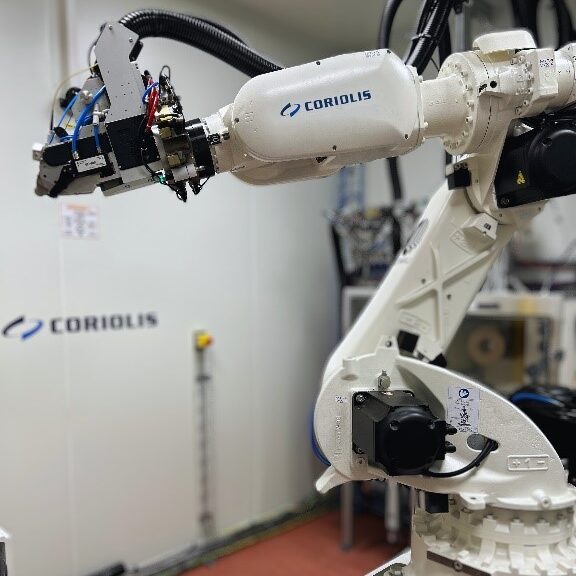

Coriolis CPico

Thermoplastic multi process technology

Advantages

Continuous fiber

Automated Fiber Placement (AFP)

Filament

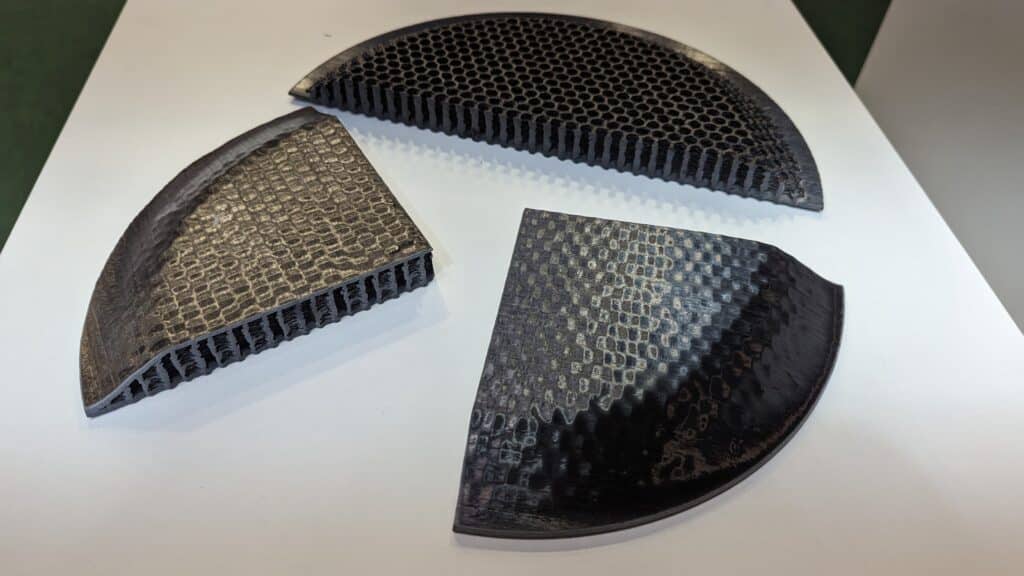

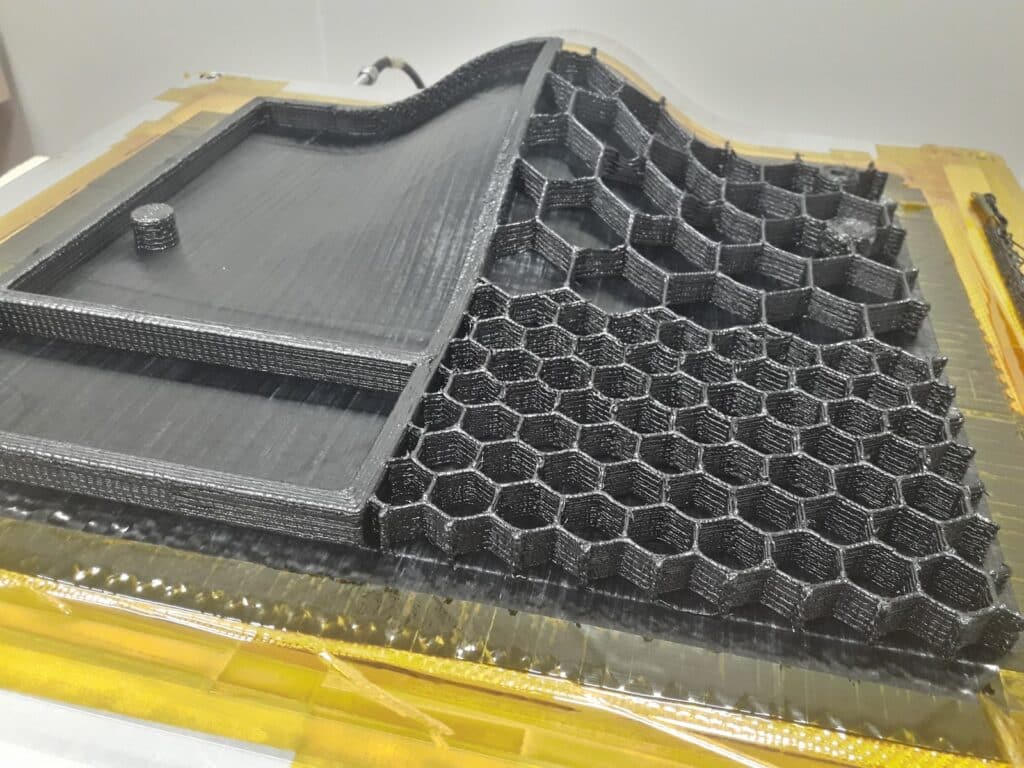

Fuze Filament Fabrication (FFF)

Pellets

Fuze Granular Fabrication (FGF)

Technical informations

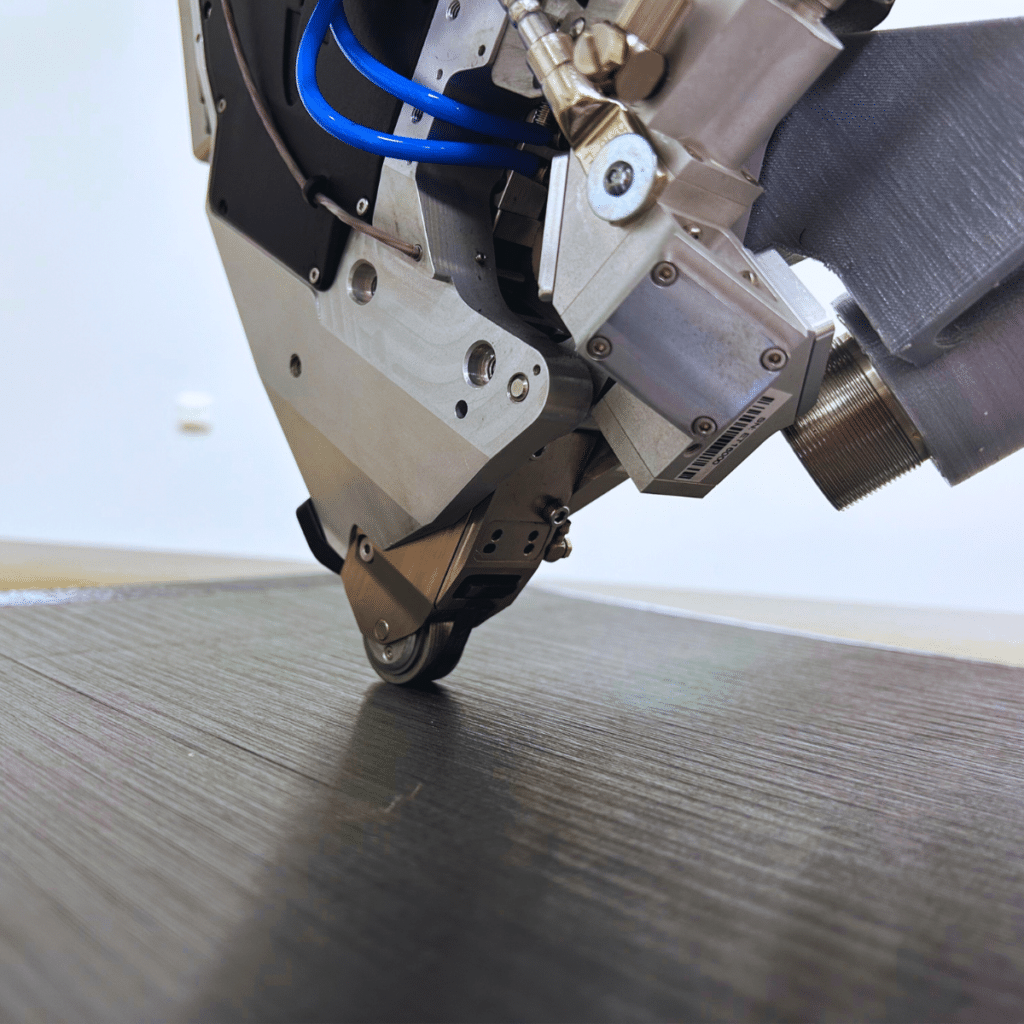

In-situ AFP/AM manufacturing in open area

| Localized heating with heating control |

| Dedicated AM nozzle design |

| Material storage with low moisture control |

Main components

| Robot | Comao NJ130-2 |

| Controller | Siemens |

| Positionner (2 axis x and y) | Comao (max 1000kg) |

| Online HMI | Coriolis |

| Programming software | Coriolis CADFiber® & AM Software |

AFP specifications

| Fiber configuration | Single fiber 1mm and 6.35mm |

| Cut and feed repeatability* | ± 2.5 mm at 300 mm/s (for AFP) |

| Maximum Layup Speed* | 300 mm/s |

| Compaction force range | 120 N |

| Tolerance between course laid up on separate tapes | +2.5/-0 mm |

| Minimum distance between cutting and feeding an individual fiber | 10 mm |

| Minimum fiber length | 37mm |

| Dynamic head compliance | ±5 mm |

| Spool in a creel house with dry air in overpressure | |

| Laser heating device | 300W |

| Fiber Tension | up to 36N |

FGF and FFF specifications

| Filament diameter for FFF | 1.75mm |

| Nozzle diameter FFF & FGF | from 0.6mm to 1.2mm |

| Heating source | air torch and cartridge heater (max 500°C |

*Depends on the material