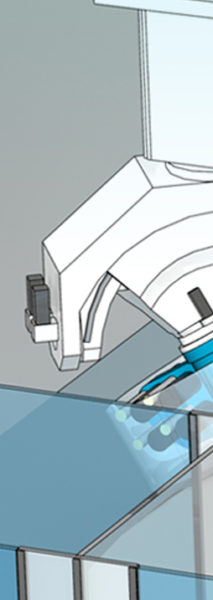

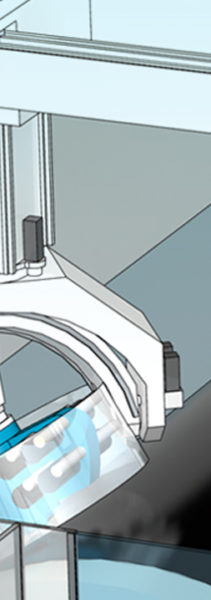

FIBER PLACEMENT DOCKABLE

HEAD FOR DOUBLE CURVATURE PARTS

ADVANTAGES

• High speed layup with gantry

• 1⁄2” thermoset, thermoplastic and dry fiber manufacturing ability

• Particularly suitable for big doubled curvature parts

APPLICATIONS

Fuselage & panel

Concave or convex panels with double curvatures

Complex parts with narrow radius

Spar & frame

High compaction around edges

Ply drop-offs and ramps over corners

Technical informations

AFP PROCESS SPECIFICATIONS

| Fiber configuration | 16*1/2’’ or 16*1⁄4’’ |

| Cut and feed repeatability* | ± 2.5 mm at at 1 m/s |

| Compaction force control | 10 N/mm |

| Temperature controls for the head | < 15°C |

| Maximum lay-up speed* | 1.2 m/s |

| Tolerance between course laid up on separate tapes | +2.5/-0 mm |

| Minimum distance between cutting and feeding an individual fiber** | 10 mm |

| Minimum fiber length* | 124 mm |

| Dynamic head compliance | ± 5 mm |

| Roller crush | ≤5 mm |

| Spool on the head | |

| HMI for advanced production management | |

| Offline programming software | Coriolis CADFiber® and CATFiber® |

| Laser heating device | |

| Infrared lamp | |

| Bar-code reader for material traceability | |

| Exchangeable head device and docking station | |

| Controller | Siemens |

CELL CONFIGURATIONS

| Gantry | |||||

| AXIS | Stroke | Speed | Acceleration | Accuracy | Repetability |

| X | 25 m | 90 m/min | 3 m.sec | ± 0.10 mm | ± 0.05 mm |

| Y | 7 m | 90 m/min | 3 m.sec | ± 0.10 mm | ± 0.05 mm |

| Z | 1,7m | 90 m/min | 3 m.sec | ± 0.10 mm | ± 0.05 mm |

| ROTARY AXIS | Stroke | Speed | Acceleration | Accuracy | Repetability |

| C1 | ± 185° | 5 rpm | 30 °/sec² | ± 50 arcsec | ± 25 arcsec |

| A | ±95° | 25 rpm | 460 °/sec² | ± 50 arcsec | ± 25 arcsec |

| B | ±45° | 15 rpm | 290 °/sec² | ± 50 arcsec | ± 25 arcsec |

| C2 | ±200° | 35 rpm | 460 °/sec² | ± 50 arcsec | ± 25 arcsec |

*Depends on the material, heat source and part shape and controller

** layup speed can be limited