Coriolis Composites helps the aeronautic industry to meet the challenges of lightweight aircrafts by implementing qualified aeronautical materials while ensuring quality and traceability.

Let’s discover our automatic solutions adapted to a wide range of specifications.

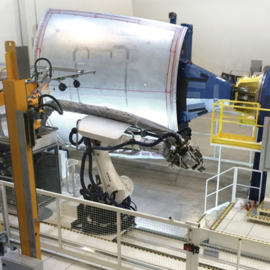

MEDIUM SIZE

FUSELAGE PANELS

Coriolis Composites’ automated fiber machines can manufacture specific panels or large-scale cylinders and double curvatures for fuselage, bulkhead and nacelle fairings.

LARGE SIZE

FUSELAGE PANELS

Our composites technology can produce complex geometrical parts with small convex radii and double curvature of variable thickness for fuselage and wings.

COMPLEX FRAMES

STRUCTURES

Our machines can also manufacture beams of variable height and double curvature, web and flanges of varying dimensions for robust frame structure.

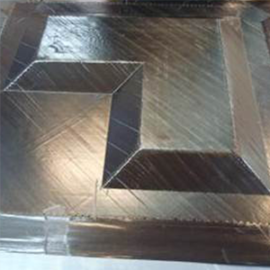

COMPLEX SANDWICH

PANELS

Coriolis’ automated fiber machines master complex layup surfaces with ramps and fragile core materials for fairings, nacelles and flaps.

MEDIUM SIZE

FUSELAGE PANELS

Coriolis Composites’ automated fiber machines can manufacture specific panels or large-scale cylinders and double curvatures for fuselage, bulkhead and nacelle fairings.

LARGE SIZE

FUSELAGE PANELS

Our composites technology can produce complex geometrical parts with small convex radii and double curvature of variable thickness for fuselage and wings.

COMPLEX FRAMES

STRUCTURES

Our machines can also manufacture beams of variable height and double curvature, web and flanges of varying dimensions for robust frame structure.

COMPLEX SANDWICH

PANELS

Coriolis’ automated fiber machines master complex layup surfaces with ramps and fragile core materials for fairings, nacelles and flaps.