At Coriolis Composites, we are passionate about industry and innovation. We started from scratch 20 years ago! That’s why, today, we stand as strong relays of the French Fab* and the European industry as a whole. Thanks to our history, we embrace a culture of no limits: we have carried out ambitious projects despite all the difficulties, without ever failing. Today, we master a unique combination in composite materials: machine, software & expertise. This allows us to support our customers from the beginning of their project with defining their needs and designing of the part itself, all the way to the implementation and optimization of AFP machines.

Clémentine Gallet, Coriolis Composites CEO, is, among others, a member of the GIFAS Aéro-PME Committee, the French Fab, and the BPI SME accelerator, and sits in the boards of directors of several industrial companies, and the ID4CAR competitiveness cluster.

* French Fab is an accreditation award created 2 October 2017 in order to federate French companies and to promote French industries throughout the world.

About

A STARTUP STORY IN THE INDUSTRY

The idea of Coriolis Composites was born in 1996, well before its founders, Clémentine Gallet and Alexandre Hamlyn, graduated from the engineering school. It is a real entrepreneurial adventure that has gone through all stages of development, including mountains to climb, arbitrations, phased deployment and finally, a genuine growth to become the flagship of the French composite industry.

FROM THE IDEA TO ITS REALIZATION

With their sidekick Yvan Hardy, the two students, without having earned their first Euro, were convinced that their idea could revolutionize a nautical industry, which was reliant on the lightness of the composites, but the manual processes of which, left room for their ingenuity. Their project was appealing, and they soon benefitted from various grants, including the ANVAR support, material loans, access to laboratories in France and Germany allowing them to make the first prototypes and file for their first patents. They finally seduced the French Ministry of Research who consequently validated their market research study. Following a number of fund-raising attempts, their project was finally brought to life thanks to the support of the regional development fund of Brittany (France). The Coriolis Composites was created and registered in Lorient in 2000 and is still today a privately-owned company.

ADAPTING TO CUSTOMER’S NEEDS

Creating a company means also knowing how to reorient a business model. This is what they refer as their second mountain to climb. They had the patents, the robots, but not their first client. Ultimately, it was their ability to adapt, as well as their persuasiveness, that enabled the sale of their first AFP machine to Airbus, which also meant changing their offer.

TRANSFORMATION AND INDUSTRIALIZATION

After Coriolis Composites had sold its first machine, it had to produce more in order to reassure its customers in a sector where certifications are complex and extremely demanding. It was no longer a question of conducting research but flying a plane!

The company also had to ensure recurring revenues to enable its sustainability. In 2010, Coriolis AFP cells manufactured the first nacelles for Safran. And in 2014, it produced the first structural parts for Airbus. Now, carbon can fly in constrained parts. This helped to convince the US market. The initial passion was turned into an industrial innovation with the development of a catalogue of standard and modular fiber placement robotic cells.

EXPORT AND GROWTH

Having successfully climbed the three mountains, Coriolis Composites is now looking into the future and concentrates on growing as a business. As a pioneer in the adoption of robotics for materials and processes, Coriolis Composites is now emerging in new industrial markets such as the automotive industry, and new export markets in the United States and China. It is also preparing for the industry of the future by mastering additive technologies, recyclable thermoplastic materials and the connected factory software.

BUILDING ON THE TEAM

The story of Coriolis Composites is built on a passion shared by the founders with all employees who have gradually joined the ranks of this industrial adventure. These highly qualified, multidisciplinary and multilingual experts are a major asset of the company and are all committed to delivering exceptional customer satisfaction.

Mission statement

A SPECIALIST IN THE IMPLEMENTATION OF COMPOSITE MATERIALS

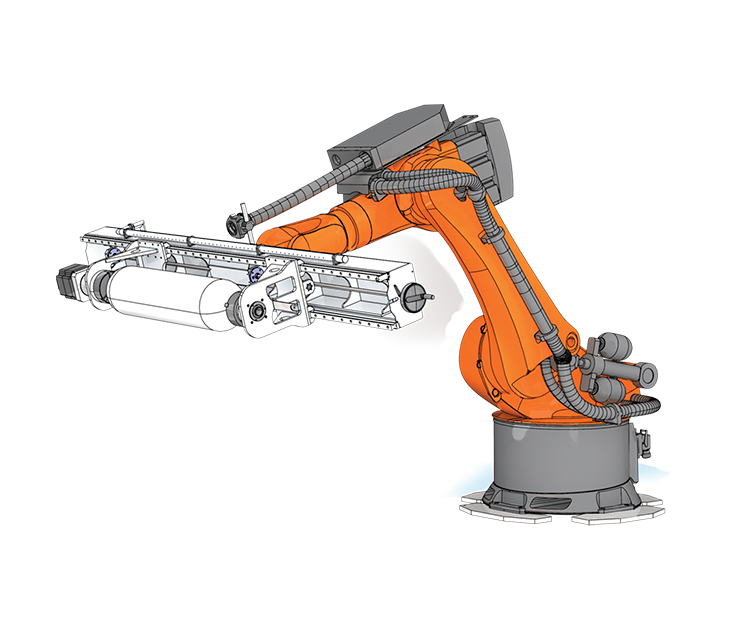

Coriolis Composites develops, makes and markets robotic cells for fiber placement using a standard robot enabling the laying of continuous or discontinuous fibers, in all directions and on complex geometrical surfaces.

Our objective is to develop and supply automated solutions for the manufacture of composite parts. The aim is to enhance mechanical performance thanks to low costs and an energy efficient, reliable technology that enables layup using a variety of composite materials.

Advantages of a global expert

Coriolis Composites is a global expert in composite technologies, developing hardware and software solutions to enhance your production and design capabilities.

Choosing the reference in automated composite additive manufacturing means accessing:

WORLDWIDE LEADER

in robotic fiber placement cells and software

1ST UNIQUE ROBOTIC TECHNOLOGY

qualified on serial production chosen by premium aerospace companies

20 YEARS

of experience in composite fiber placement including laser heating devices for dry fiber and thermoplastics

FULL SERVICE

customer support in composite manufacturing

WORLDWIDE PRESENCE

in 12 countries with 6 subsidiaries and 6 partners

FIFTY FAMILIES OF PATENTS

extended in relevant countries (Europe, USA, Brazil, China, Japan, Korea…) and six trademarks registered in France and abroad

Why choose automated composite additive manufacturing

LIGHT, STRONG AND COST-EFFICIENT

Composite materials outperform traditional materials. They reduce complexity, weight and energy consumption. They adopt intricate geometries whilst remaining highly resistant. They enhance competitiveness and enable new product designs. They are the fabric from which the future is made.

AFP SYSTEMS FROM CORIOLIS COMPOSITES

Aircraft manufacturers have paved the way for the large-scale industrialization of composite materials, closely followed by the automotive industry. Tomorrow, our mobility will largely rely on composite materials. New instruments for composite manufacturing will further spur the ongoing industrial metamorphosis.

Coriolis Composites has inspired and driven the advent of Automated Fiber Placement (AFP) additive manufacturing.

Today, our robotized solutions for the series production of composite structures are being adopted by industry leaders around the world.

Together with our clients, we analyze new program requirements and demonstrate feasibility in our Technical Center. We then deliver fully industrialized solutions for reliable, fast and cost-efficient manufacturing – from the very start of series production.

MF TECH

The worldwide reference in composite filament winding joined Coriolis Composites in 2018 to extend the Coriolis Group wide scope in AFP additive manufacturing.

SUPPLYING ROBOTIC FILAMENT WINDING

Founded in 2004, MF TECH has 18 employees and is based in Argentan, France. It is a global benchmark company in the field of robotic filament winding, a technique used in the manufacturing of composite parts such as tubes, mechanical parts and vessels.

The robots developed by MF TECH are currently used in multiple sectors including automotive, aeronautical and aerospace, defence, nuclear, medical and even sports.

TECHNOLOGICAL AND COMMERCIAL SYNERGIES

Together the two companies benefit from the relationships established by Coriolis Composites with the major aerospace contractors, profiting from an international network in USA, Canada, China, Germany and the UK as well as the perfect reputation of MF TECH in the automotive sector.

THE FIRST EXTERNAL GROWTH FOR CORIOLIS GROUP

I am extremely pleased with the collaboration between our two companies, both of which are at the cutting edge of robotics technology within their respective fields. We share the same culture of innovation and the same vision of the role to be played by robotics within the composites field. Together we will be able to offer a complete package, unique in the market, to all our customers. This is an important stage in our strategic plan designed to see our Group become a global leader in industrial robotics for the manufacturing of composite parts ‒ a market offering significant potential over the long term.

Clémentine Gallet, President of Coriolis Group, parent company of Coriolis Composites

Benefits of our AFP cells

ASSURING RELIABILITY AND COST-EFFICIENCY

We have developed proprietary technology to guarantee the reliability and performance of our AFP solutions. Our highly modular and standardized systems include:

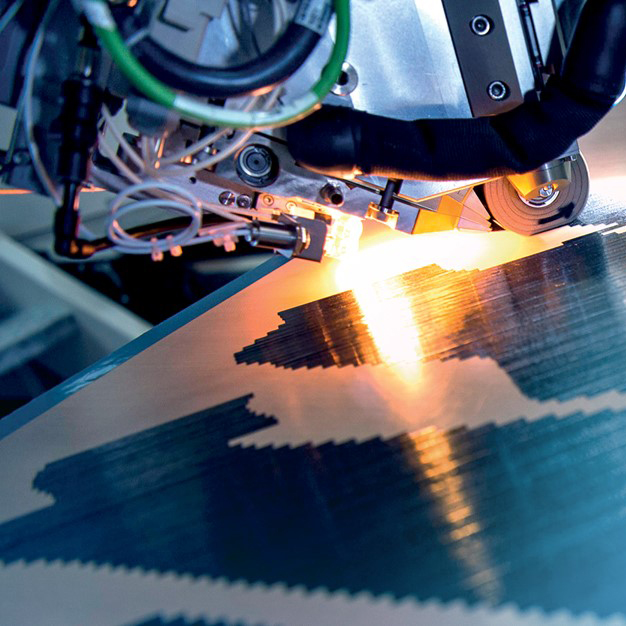

/ A compact, precise and agile AFP head for dynamic tow control, including cutting, feeding, compacting and heating

/ A standard articulated robot and complementary mold rotator, for spatial positioning

/ A remote creel for cooled storage of tow spools and tow tension control

/ An optional linear rail for robot and creel, enabling the manufacturing of very large structures

/ An integrated software suite for offline design, optimization, machine simulation, programming and production control

/ A reactive service and maintenance team close to your production sites

ENHANCING VERSATILITY AND PRODUCTIVITY

Our technology has proven its maturity in large-scale industrial programs. It offers the combination of versatility and productivity required for the series production of composite parts:

/ From simple to highly complex geometries

/ Honeycomb sandwich structures

/ Ramping on non-constant sections

/ Strongly curved, concave and convex shapes

/ Thermoset, thermoplastic and dry fiber processes

/ Bi-directional operations and ultra-short cut lengths

ACCELERATING INDUSTRIALIZATION

The manufacturing of composite structures requires intensive evaluation and preparation. Our Technical Center offers a unique test-bed facility for developing, testing and validating solutions under industrial conditions. A team of engineers, dedicated to your specific project, ensures safe and reliable series production right from start:

/ Preparing, evaluating and optimizing series production

/ Generating kinematic control for optimized fiber lay-up

/ Assuring the delivery of a mature, tried-and-tested production tool > Transferring skills and training the production team Laser